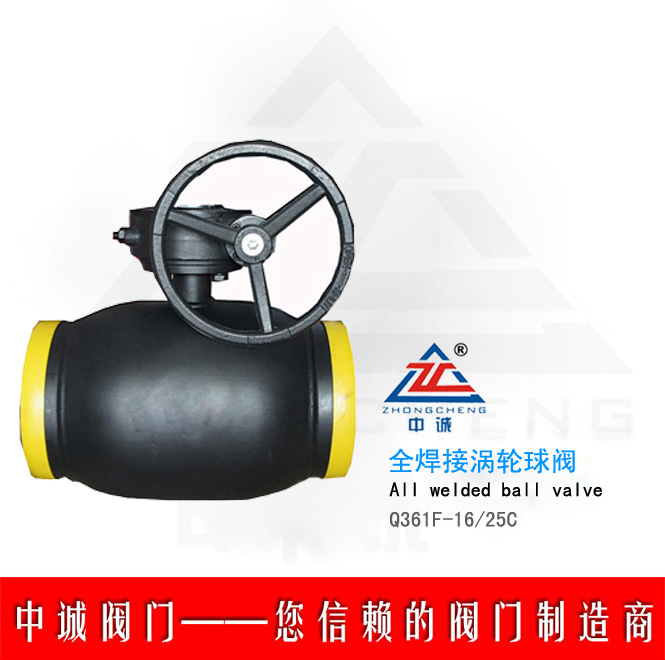

Q361F-16 full welded ball valve

q361f full welded ball valve's brief introduction:

Q361f full welded ball valve full welded ball valve is widely used in each domain, its superior quality and high performance stability is out of reach for ordinary cast steel ball valve, the service life of full welded ball valve is far greater than cast steel ball valve, full welded ball valve is widely used in city gas, city for thermal, petrochemical industry, shipbuilding, steel, gas station, power plants and other kinds of pipe devices.All welded ball valve can be directly buried underground, need not well built tall valve to reduce the project cost, but also can avoid the operation of the valve cause harm to the staff, full welded ball valve can be used long-term reliable operation, the valve under the condition of normal operation, the quality assurance period of 20 years.

Second, the q361f full welded ball valve key features:

1, the body structure and welding, there would be no external leakage phenomenon.

2, seat consist of ptfe sealing ring and spring adaptable to changes in pressure and temperature, within the scope of use does not produce any leakage.

3, the valve stem leakage structure, there is one at the bottom of the valve stem ptfe valve seal and 1 type o sealing ring, which has two type o sealing ring, two of ptfe gasket, ensure no leakage.

4, the valve body material is the same as the pipe material, there will be no stress not divide evenly, also won't because of the earthquake and the vehicle through the ground and sometimes extrusion deformation.

5, light body and easy to heat preservation.

6, buried type ball valve can be directly buried underground, need not build tall valve well, only need to set up small shallow Wells on the ground, greatly reduce the construction cost and project time.

7, can be adjusted according to the requirements of the pipeline construction and design of the length of the body and stem height.

8, the machining accuracy sphere very precision, convenient operation without adverse interference.

9, have both welding and flange connection.

10, mode of operation: handles, gear (vertical/horizontal)

11, the valve under the condition of normal operation, the quality assurance period of 20 years.